- Free shipping to mainland Spain for orders over 300€.

Victron LiFePO4 Lithium Battery 12,8V 150Ah NG - BAT512115620

644,63€

TAXES INC.

- Rated voltage: 12.8 V

- Rated capacity at 25º: 150 Ah

- Number of cycles: 80%: 2500 cycles / 70%: 3000 cycles / 50%: 5000 cycles

- Maximum load current: 150 A (1C)

Product available for sale

Finance your purchase with Cetelem

Reference:

BAT512115620

Categories: Lithium Batteries 12V, Solar batteries

Details of the Victron LiFePO4 Lithium Battery 12,8V 150Ah NG - BAT512115620

Victron LiFePO4 Lithium Battery 12,8V 150Ah NG - BAT512115620

The Victron LiFePO4 12,8V 150Ah NG lithium battery is a lithium iron phosphate battery which has an integrated shunt and has IP65 protection. It can be connected in parallel, in series and in series/parallel combination, up to a maximum of 50 batteries per BMS NG. The maximum energy storage for a system consisting of 50 150Ah batteries is 96kWh.

The shunt records the battery voltage, current and temperature and sends the data to the NG BMS, which evaluates the data to calculate certain parameters and set alarms. This data can be monitored via the VictronConnect App or with the use of a GX device and the Victron VRM portal.

This lithium battery belongs to Victron's NG (New Generation) series, which also consists of 25.6V and 51.2V batteries of different capacities.

Victron LiFePO4 Battery Specifications 12.8V 150Ah NG

- Rated voltage: 12,8 V

- Rated capacity at 25 °C: 150 Ah

- Rated energy at 25 °C: 1920 Wh

- Loss of capacity: <1 % per 100 cycles, at 25 °C, with a depth of discharge of 100 % of usable capacity.

- Energy loss: <1 % per 100 cycles, at 25 °C, with a depth of discharge of 100 % of usable capacity.

- Full cycle efficiency: 92 %

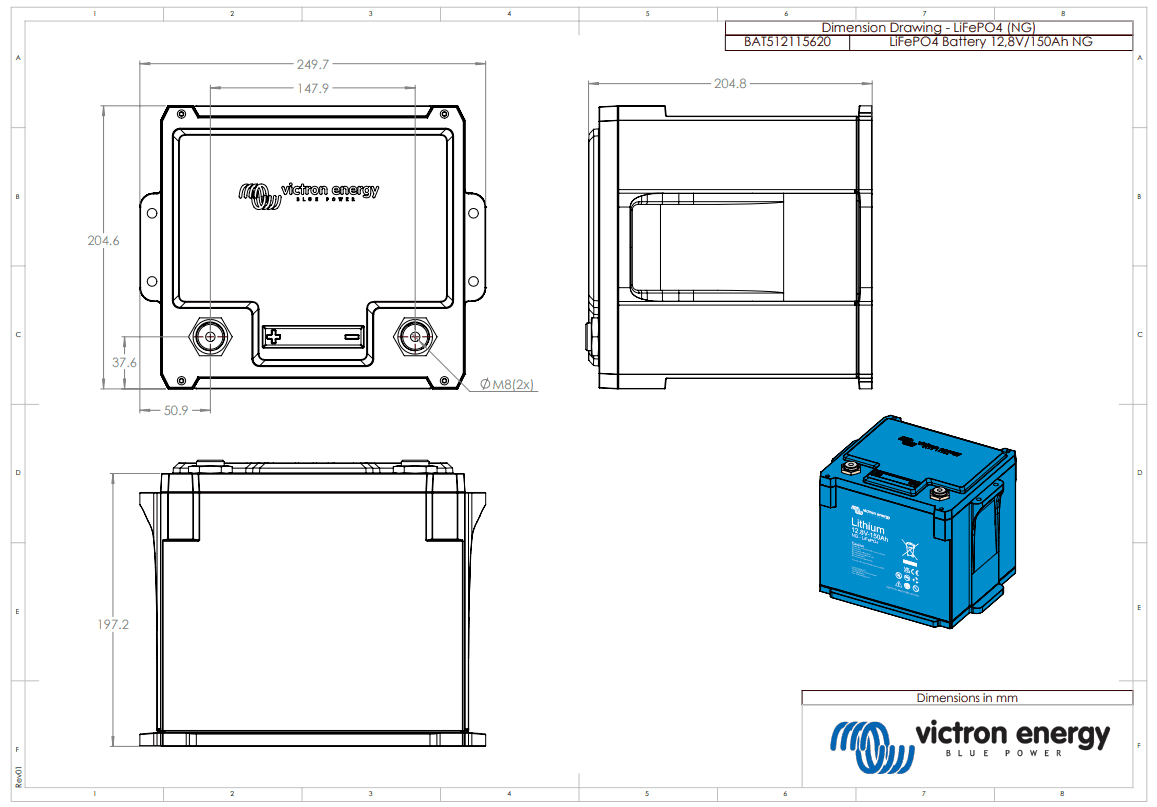

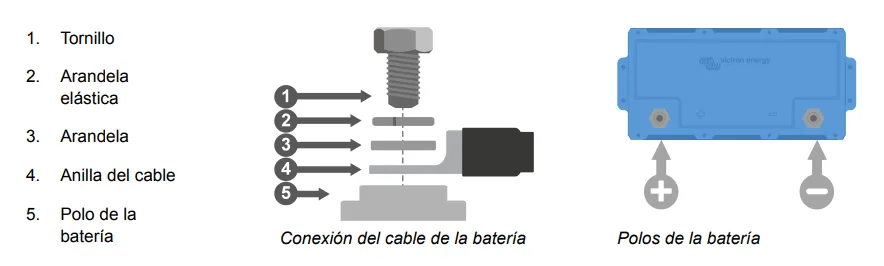

- Battery connections: Screws M8 (For cables with 8mm round cable lug)

- Cycle life (capacity ≥ 80 % of nominal):

- 80 % discharge: 2500 cycles

- 70 % discharge: 3000 cycles

- 50 % discharge: 5000 cycles

- Internal self-discharge: less than 3 % per month at 25 °C temperature.

- Dimensions: 205 x 250 x 205 mm

- Weight: 14 Kg

Discharge capacity

- Maximum continuous discharge current: 150A (1C)

- Maximum discharge current per 10s intervals: 300 A (2C)

- Voltage at the end of the discharge: 11.2 V (Minimum battery voltage).

- Internal resistance: 2 mΩ

Carrying capacity

- Charging voltage:Between 14.00V and 14.40V

- Floating tension:13,5 V

- Maximum continuous load current: 150 A (1C)

- Maximum load current per 10s intervals: 225 A (1.5C)

Working conditions of the Victron lithium battery 12,8V 150Ah NG

- Working temperature:

- Discharge: From -20 °C to +50 °C

- Load: +5 °C to +50 °C

- Storage temperature: From -45 °C to +70 °C

- Humidity (non-condensing): Max. 95 %

- Protection class: IP65

General aspects to be taken into account

- Specific BMS for the NG battery series: A BMS compatible with the new NG series must be used, such as the Lynx Smart BMS NG 500 A / Lynx Smart BMS NG 1000 A (with M10 busbars). These NG BMSs must be purchased separately from the battery.

- Separate measurements of each cell: Individual cell voltages and temperatures in addition to battery current.

- Battery BMS interface: Male + female cable with M8 circular connector with high-speed digital communication and 50 cm length

- Bluetooth: NG lithium batteries do not have Bluetooth because it is built into the NG series BMS.

- Maximum number of batteries: 50 units (Total 384 kWh per BMS NG)

- Battery firmware updates: The firmware is automatically updated by the BMS NG.

- Repairable: Yes (cover can be removed with screws)

- Safety standards:

- Cells: UL1973, UL9540A, IEC62619

Installation and assembly of LiFePO4 12,8V 150Ah NG battery

The following image shows the dimensions of the 12,8V 150Ah NG battery:

Mounting Victron 12.8V 150Ah NG lithium battery:

- It can be mounted vertically or on its side, but never with the terminals facing downwards.

- With two optionsis for fixation: straps or mounting brackets.

- With the mounting brackets the battery is well secured and cannot slide or tip over.

- It can only be installed indoors and in a dry place.

- Due to its weight, 14Kg, the use of handling equipment is recommended for transport.

- A space of 2 cm should be left around the battery to allow for ventilation (the battery heats up during charging and discharging).

- Special attention must be paid to polarity when connecting the terminals. The screws are tightened with a torque of 10 Nm, using a tool suitable for the size of the screw head. The picture below shows how the wires should be connected:

- The installation of a BMS NG, Lynx Smart BMS NG 500 A/ Lynx Smart BMS NG 1000 A (purchased separately) is mandatory.

- The BMS manages all battery parameters. It detects the system voltage and the number of batteries connected in series, in parallel and in series/parallel combination.

- If you want to monitor the system, you need the BMS NG and the VictronConnect App or a GX device and the VictronConnect App. Victron VRM portal. You can see the parameters of the lithium battery in real time.

Connection of BMS NG to Victron 150Ah NG battery

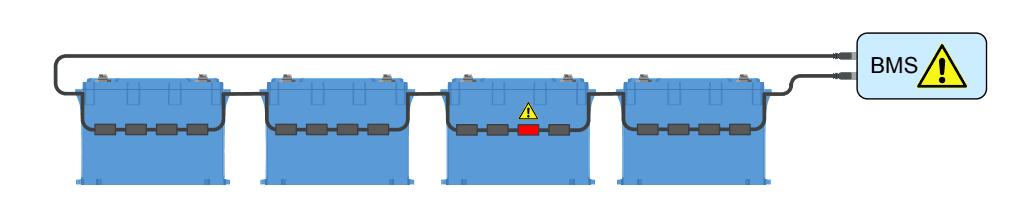

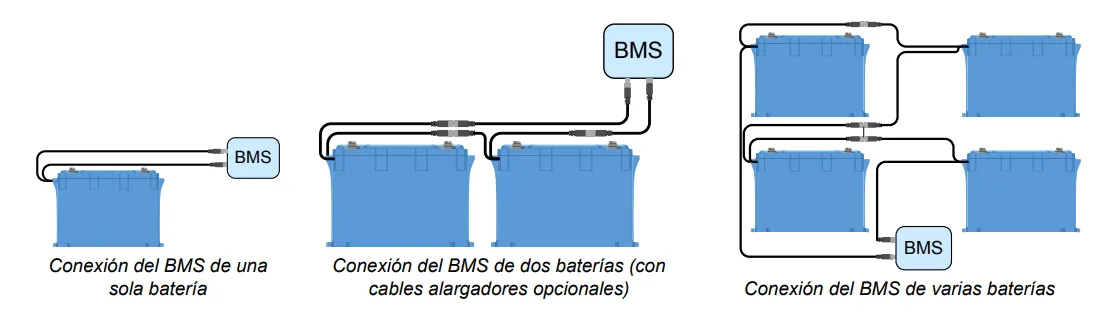

- Each NG battery has two cables to communicate with the NG BMS. One has a male and one has a female connector, both with three poles. Depending on the battery model, the BMS NG cables can be placed on the same side of the battery or on both sides.

- BMS cables are 50cm long, they can be extended with BMS NG extension cables.

- With a single NG battery, the cables are connected directly to the NG BMS.

- In multi-battery systems, all BMS cables are daisy-chained with the first and last cable going to the BMS NG.

Cable cross-section and fuses for installation of the LiFePO4 12,8V 150Ah NG battery

All electrical connections to the battery must have a fuse suitable for the size of the battery cable. And the battery cables must be sized to carry the maximum current expected in the system.

For more information on sizing, see the Victron guide. "Wired without limits". You can also install the Victron Toolkit App and calculate the cable cross-section you need.

Cable recommendations to be used for a distance of 2m between inverter and battery:

- For this 12,8V 150A/h lithium battery: minimum 50mm section.

Insert the fuses

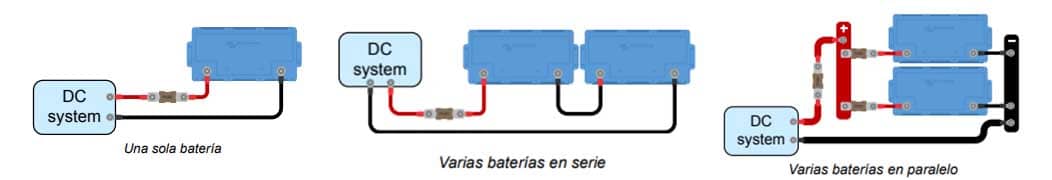

Parallel connection:

- A total of 50 lithium batteries can be connected.

- The fuse of each lithium battery must be placed on the positive side.

- The cables of the DC system are connected diagonally.

- The cable cross-section of the system shall be equal to the cable cross-section of the chain multiplied by the number of chains.

- There are as many strings as the number of batteries in parallel.

- The fuse is placed in the main positive cable leading to the battery bank.

Serial connection:

- A maximum of four 12.8 V batteries or two 25.6 V batteries can be connected in series. This gives a total of 51.2 V.

- Before connecting the batteries in series, each battery must be fully charged and individually balanced.

- The negative is connected to the positive of the next battery.

- The fuse is placed in the positive part of the chain.

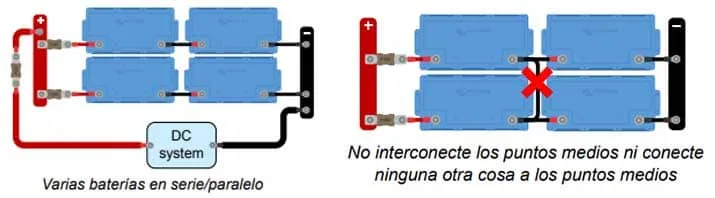

Serial/parallel combination connection:

- Up to 50 lithium batteries can be connected.

- Before connection, each battery must be fully charged and individually balanced.

- The fuses are placed on the positive side.

- Do not interconnect the midpoints with each other or connect anything else to them.

- The system cables are connected diagonally.

- The cable cross-section of the system shall be equal to the cable cross-section of the chain multiplied by the number of chains.

- The fuse is placed in the main positive cable leading to the battery bank.

Charger settings

-

- Absorption voltage: 14.2 V.

- Float voltage: 13.5 V.

- Absorption time: 2 hours.

- For more information: section "First charge of the lithium battery".

Use the checklist in the manual (link at the end of the sheet) to check all connections and wiring of the system.

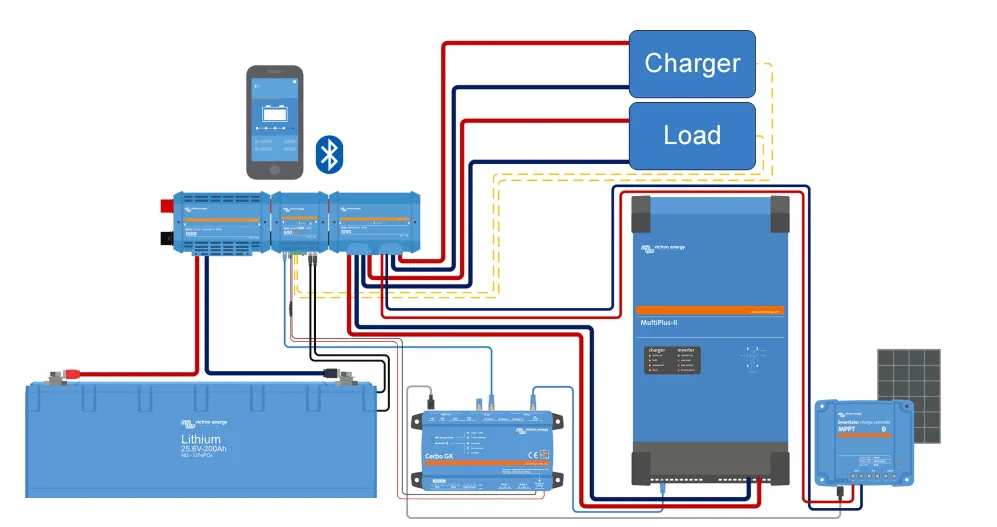

Example of NG battery installation

The picture below shows an example of a typical system installation of an NG battery and an NG BMS:

This installation consists of:

- Victron NG lithium battery.

- Lynx Smart BMS NG 500 A.

- Lynx Class-T power in (M10).

- Lynx Distributor (M10).

- Smart Solar MPPT charge controller.

- Inverter Multiplus II.

- Cerbo Gx monitoring.

- VictronConnect App.

- One charger and one charge.

- Solar panels.

List of materials required for the installation of the 12,8V 150Ah NG battery

- As stated in the section "Installation and assembly", the BMS NG is mandatory:

- Lynx Smart BMS 500 NG (M10) Victron - LYN034160310

- Lynx Smart BMS 1000 NG (M10) Victron - LYN034170310

- If necessary, 1m, 3m or 5m extensions can be purchased for the BMS cables: Victron cable with 3-pole male/female M8 circular connector 3m - ASS030560300

- The monitoring can be done through the VictronConnect App with the Bluetooth connection of the BMS NG or by installing a GX device: Victron Cerbo GX MK2 Monitoring - BPP900451100 and with the Victron VRM portal.

- A screen can also be added to the installation: Monitoring Victron GX Touch 50 - BPP900455050.

- With a Cerbo GX installed, the system can be monitored from anywhere and at any time via the VRM portal. The VictronConnect App is limited to the Bluetooth range of the BMS NG and the app must be open, as it does not run in the background.

First charge of the LiFePO4 battery

Not all batteries have the same state of charge at the time of installation due to conditions during transport, storage, and because they come from the factory with a charge of approximately 50%.

To connect batteries in series, they must first be charged separately with a charger or a dedicated inverter/charger with a BMS; due to the large differences in the state of charge between the batteries to be connected. These differences are not the same as imbalances between the cell voltages of a battery. This is because the cell balancing circuits of one battery cannot affect the cells of another battery.

If they are connected in parallel, it is not necessary to charge them before connecting them as they can be charged as a unit.

Loading process:

- First you have to configure the charging profile in the charger with the recommended settings:

- It must be a 12V charger and must have a profile for charging LiFePO4 batteries or allow a custom profile to be made.

- Absorption voltage: 14,2 V.

- Absorption time:

- Between 4 and 8 hours per month for systems with high usage (stand-alone or ESS type).

- Minimum 2 hours per month for systems with little operation, such as auxiliary applications or UPS.

- Floating tension: 13,5 V.

- Values that not all chargers have:

- Storage mode: same value as the buoyancy stress.

- Initial charging voltage: same value as the absorption voltage.

- No temperature compensated charging is required for lithium batteries. Set to: 0mV/°C.

- A charging current of 0.5C is recommended. In the case of a 150 Ah lithium battery, the charging current would be 75A.

- The battery, the BMS NG and the charger must communicate with each other. To check this, disconnect one of the cables from the battery to the BMS NG and see if the charger switches off. When you reconnect the cable, the charger should turn on.

- Turn on the charger and check that it charges the battery.

- If, during charging, there is any imbalance between the battery cells, it is possible that the BMS NG will repeatedly switch the charger off and on. This will be repeated until

that the cells are balanced and the charger will not switch off until the battery is fully charged.

- If, during charging, there is any imbalance between the battery cells, it is possible that the BMS NG will repeatedly switch the charger off and on. This will be repeated until

- The battery is fully charged when the battery charger has reached the float state and the cells are in the "balanced" state. If the state of the cells is "unknown" or "unbalanced", the battery charger will restart several times until it is "balanced".

Battery management system (BMS NG)

When the BMS NG firmware is updated, the battery firmware is also automatically updated. This can be done via the VictronConnect App or via the VRM Portal. The App must be updated to have the latest firmware version available.

Functions performed by the BMS NG:

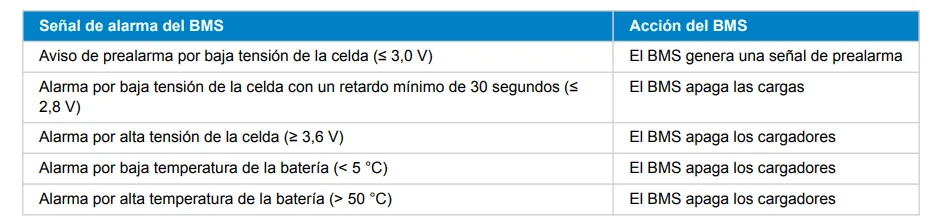

The BMS NG has two ways of controlling loads and chargers:

- Sending an electrical or digital on/off signal to the charger or load.

- By physically connecting or disconnecting a load or charging source from the battery. Directly or by using a BatteryProtect or a Cyrix Li-ion relay.

The Lynx Smart BMS NG is used in systems containing DC loads and AC loads via inverters or inverter/chargers. This BMS NG is equipped with a contactor that disconnects the DC system, a "load process disconnect", a "load disconnect", a "pre-alarm" contact and a battery monitor. It can also be connected to a GX device and Victron Energy compatible control equipment via DVCC.

- In case of low cell voltage, the BMS NG will send a "load disconnect" signal to switch off the load(s).

- Before shutting down a load, it will send a pre-alarm signal indicating impending low cell voltage.

- In case of high cell voltage or low or high battery temperature, the BMS NG will send a "load disconnect" signal to switch off the charger(s).

- If the batteries are further discharged (or overcharged), the contactor will open, effectively disconnecting the DC system to protect the batteries.

Operating conditions

- Charging must be done in a temperature range of +5°C to +50 °C:

- If the temperature is less than or equal to 15 °C: the charging current must be reduced to a maximum of 0.3C.

- If the temperature is higher than 35 °C: the load current must also be reduced.

- The discharge must be carried out in a temperature range of -20 °C to +50 °C:

- If the temperature is 0°C or below: the discharge current must be reduced to 0.5C.

- If the temperature is higher than 35 °C: the discharge current must also be reduced.

Victron NG LiFePO4 Battery Maintenance

- Total discharge should be avoided.

- The system must be prevented from shutting down when the BMS NG pre-alarm is activated.

- If the BMS NG deactivates the loads, the batteries must be recharged immediately. The batteries should spend as little time as possible in a deeply discharged state.

- The charging process must not be interrupted until the state is "balanced" for all batteries in the system.

- If the system is not to be used for a period of time, the batteries must be left charged and the DC system must be disconnected.

Battery storage

- Avoid direct sunlight, high temperatures and high humidity.

- Store in a cool (optimum temperature +25 ±5°C) and ventilated place.

- Leave an adequate distance between the walls and the coil to ensure proper ventilation.

- Store lithium batteries in plastic or non-conductive trays.

- In case of long-term storage:

- Do not store upside down.

- Charge the battery at 40-60 % initially and check the open circuit voltage monthly.

- Charge immediately if the voltage drops below 3.0 V/cell.

- A charge is required every six months.

Victron LiFePO4 Lithium Battery 12,8V 150Ah NG - BAT512115620 manual and datasheet

In case you have any doubts, here you have the manual and the technical data sheet of this LiFePO4 lithium battery:

Manual lithium battery LiFePO4 Victron 12,8V 150Ah NG - BAT512115620

Datasheet lithium battery LiFePO4 Victron 12,8V 150Ah NG - BAT512115620

Weight and dimensions

| Weight | 14 kg |

|---|---|

| Dimensions | 20,5 × 25 × 20,5 cm |

User feedback

Be the first to review "Victron LiFePO4 Lithium Battery 12,8V 150Ah NG - BAT512115620" Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.