- Free shipping to mainland Spain for orders over 300€.

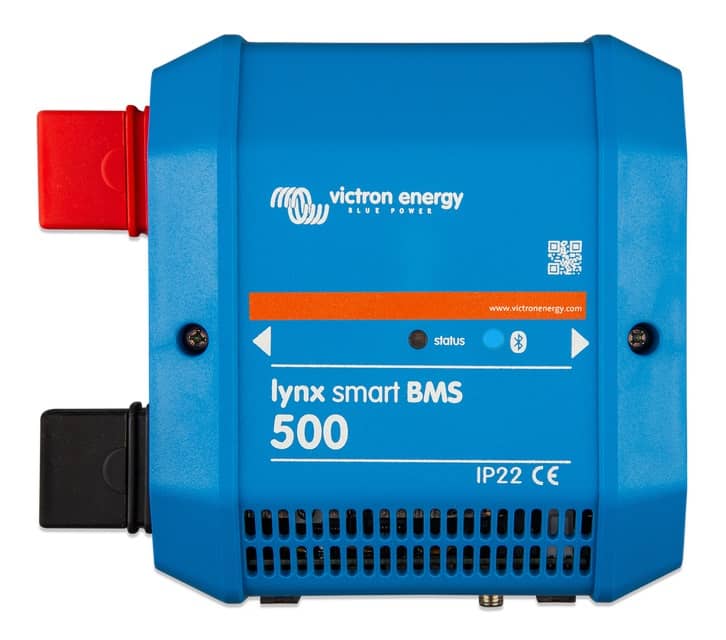

Lynx Victron Victron Smart BMS 500 M10 - LYN034160210

685,03€

TAXES INC.

Battery voltage range: 9 - 58 VDC

Maximum input voltage: 75 VDC

Accepted system stresses: 12, 24 or 48 V

Product available for sale

Finance your purchase with Cetelem

Reference:

LYN034160210

Categories: Accessories for solar batteries, Solar batteries, BMS for lithium batteries

Details of the Lynx Victron Victron Smart BMS 500 M10 - LYN034160210

Lynx Victron Victron Smart BMS 500 M10 - LYN034160210

Lynx Victron Smart BMS 500 M10 - LYN034160210 is the advanced solution for the management and protection of Victron's LiFePO4 lithium batteries. Ideal for energy storage applications and photovoltaic installations, this BMS ensures safe and efficient performance of the batteries in the system. It features state-of-the-art monitoring, control and protection functions.

Features of the Smart BMS 500 M10

- Integrated 500 A contactor:

- The integrated contactor is a secondary safety measure, protecting the battery in the event that the main controls have not correctly deactivated the loads or chargers. This contactor also serves as the main switch for the system and can also be remotely controlled.

- Pre-load circuit:

- It avoids high inrush currents when connecting capacitive loads, such as inverters (MultiPlus, Quattro); the need for an external pre-charging system is eliminated. This ensures a smooth start-up of the system.

- Bluetooth Remote Monitoring:

- The Lynx Smart BMS can be controlled and monitored remotely via the VictronConnect app or a GX device such as the Cerbo GX MK2. Access real-time data on state of charge, voltage, current, ... And with the Instant Readout function, you get quick diagnostics without the need to connect directly to the BMS.

- Automatic Control of Chargers and Inverters:

- The system automatically manages compatible Victron inverters and chargers via DVCC, using the ATC (allows charging) and ATD (allows discharging) contacts to control other devices that have a remote port.

- Programmable Relay:

- The integrated relay in the Lynx Victron Victron Smart BMS 500 M10 is programmable for various functions, such as activating alarms or controlling an alternator via an external regulator. The system ensures that the alternator is switched off before the battery is disconnected, thus protecting all components.

- AUX Power Terminal (1.1 A):

- The AUX output provides 1.1 A of power to supply devices such as a GX device, even when the BMS shuts down loads due to low cell voltage. If 5 minutes pass with no load voltage detected, the BMS automatically shuts down, including the AUX output.

- VE.Can and NMEA 2000 Data Communication:

- Thanks to VE.Can technology, connection to GX devices is via a standard RJ45 network cable. In addition, the NMEA 2000 protocol allows the BMS to be integrated into nautical networks, sending information directly to multifunctional displays on board.

- Lynx Distributor Fuse Monitoring:

- The Lynx Victron Smart BMS 500 M10 - LYN034160210 can monitor up to four Lynx distributors and their fuses. Via VictronConnect or a GX device, you can read the status of the fuses and receive alerts if any of them blow, thus preventing possible system failures.

- Parallel Redundancy

- The Lynx Smart BMS and Lynx Smart BMS NG series allows for multiple Lynx BMS in an installation. Each Smart BMS 500 M10 has its own battery bank and together they form a single redundant battery system. Up to five BMS can be connected in parallel

Lynx Victron Victron Smart BMS 500 M10 Specifications

- Battery voltage range: 9 - 60 VDC

- Maximum input voltage: 75 VDC

- Accepted system stresses: 12, 24 or 48 V

- Reverse polarity protection: No

- Rated continuous current of the main safety contactor: 500 ACC continuous

- Rated peak current of the main safety contactor: 600 A for 5 minutes

- Power consumption in OFF mode: 0,3 mA for all system voltages

- Standby power consumption: Approximately 0.6 W (50 mA at 12 V)

- Power consumption in ON mode: Approximately 2.6 W (217 mA at 12 V) depending on the relay status

- Minimum load resistance for pre-loading: 10 Ω and higher for 12 V systems 20 Ω and higher for 24 V and 48 V systems

- Maximum rated current of the AUX output: 1.1 A continuous, protected by a resettable fuse

- ATC port (enable charging) Maximum rated current: 0.5 A at 60 VDC, protected with a resettable fuse

- ATD port (enable discharge) Maximum rated current: 0.5 A at 60 VDC, protected with a resettable fuse

- Single-pole double-touch alarm relay (SPDT) Maximum rated current: 2 A at 60 VDC

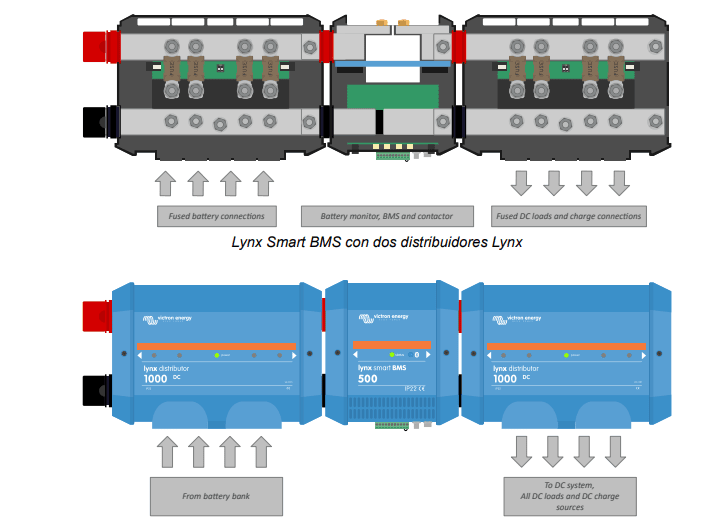

Integration into the Lynx distributor system

The Lynx Smart BMS integrates easily with the Lynx distributor system. The battery should always be connected to the left side of the Lynx Smart BMS (in the normal position), while all loads and chargers should be connected to the right.

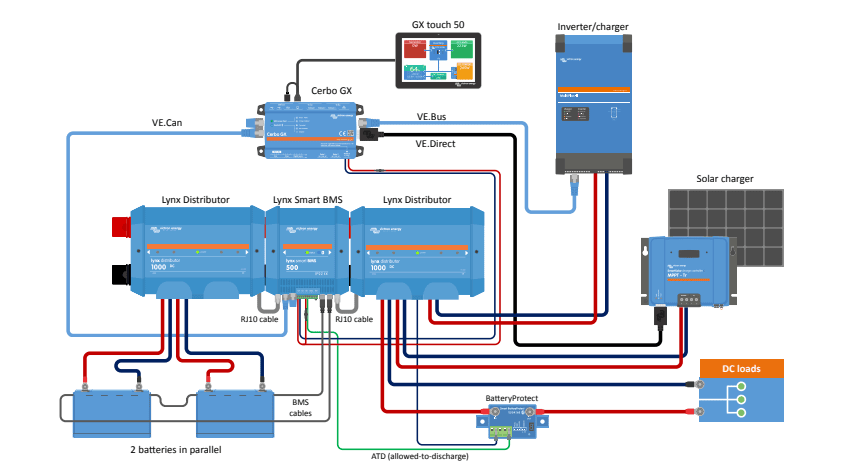

The picture below shows the Lynx Smart BMS in a system with two Lynx distributors. Together they form a continuous busbar with fused battery connections, battery monitor, BMS system, contactor and fused load connections.

Lynx modules can be mounted in any orientation, the units are fitted with special adhesives so that they can be installed upside down.

Sizing of the BMS system

Lynx Smart BMS rated current

The main safety contactor of the Lynx Smart BMS has a continuous current rating of 500A and a peak current rating of 600A for 5 minutes. If the peak current limit or 5 minute interval is exceeded: an overcurrent alarm will be generated and ATC or ATD (allow to charge or allow to discharge) will be disabled after 30 seconds.

Power rating of Lynx Smart BMS at different voltages:

- 12V: 6kW

- 24V: 12kW

- 48V: 24kW

Fuses and wiring

The BMS does not function as a fuse, it only warns if the current is too high. The fuse function must be done externally. Always use fuses with the correct rated current and voltage and cables with a cross-section sufficient for the maximum rated current of the system.

For more information, please refer to the Victron manual. Wired without Limits.

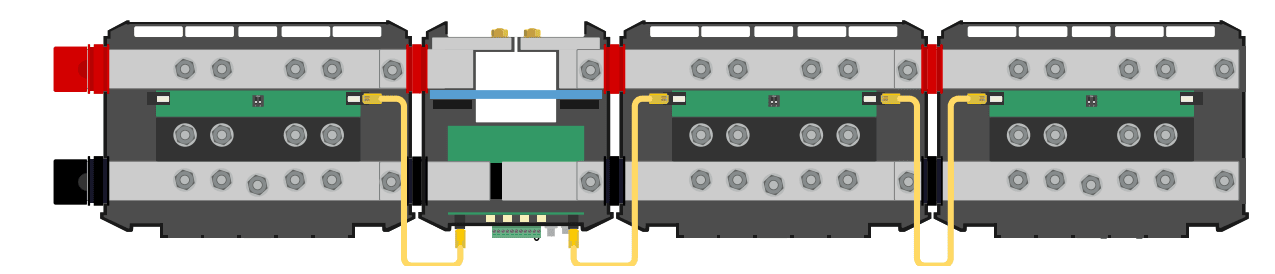

Assembly of Lynx modules

- If the Lynx system is to be connected on the right hand side and the Lynx module has a plastic barrier on the right hand side, remove it. If the Lynx module is the one on the right-hand end, leave the plastic barrier in place.

- If the Lynx modules are to be connected on the left, remove the red and black rubber sleeves. If the Lynx module is the left-most module, leave the red and black rubber sleeves in place.

- Remember that in a Lynx Smart BMS, the battery is connected on the left side and the DC system on the right side.

- Connect all Lynx modules together with the holes and screws on the left and right. Be careful to fit the modules correctly into the rubber connection slots.

- Place the washer, spring washer and nut on the bolts in the correct order and tighten the nuts with a torque of 14 Nm for M8 models and with a torque of 33 Nm for M10 models (17 Nm for units with a serial number earlier than HQ2340XXXX).

RJ10 cable connection

This is the sequence of steps to connect the RJ10 cables between the Lynx Smart BMS and the Lynx distributor:

- Plug one end of the RJ10 cable into the RJ10 connector on the Lynx distributor, with the retaining clip on the RJ10 connector facing away from you.

- Pass the RJ10 cable through the slot at the bottom of the Lynx distributor.

- Plug the RJ10 cable into the RJ10 connector on the bottom of the Lynx Smart BMS.

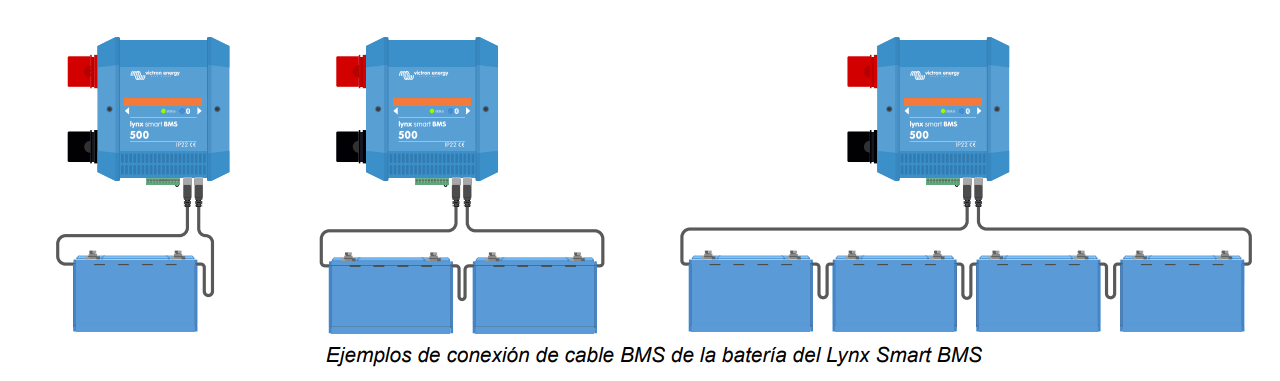

Connection of BMS cables

Up to 26 batteries can be connected to the BMS. If multiple batteries are used, first interconnect the BMS cables of the battery and then connect the BMS cable of the first and last battery to the BMS connectors of the Lynx Smart BMS.

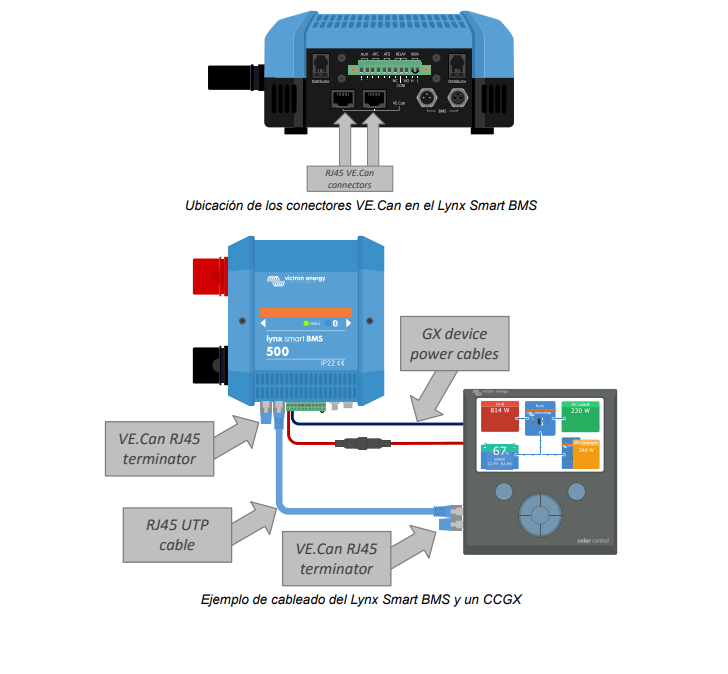

Connecting the GX device

Connect the VE.Can port of the Lynx Smart BMS to the VE.Can port of the GX device using an RJ45 cable. Several VE.Can devices can be daisy-chained, but make sure that the first and last devices have a VE.Can RJ45 terminator installed. Power the GX device from the AUX + and AUX - terminals on the Lynx Smart BMS.

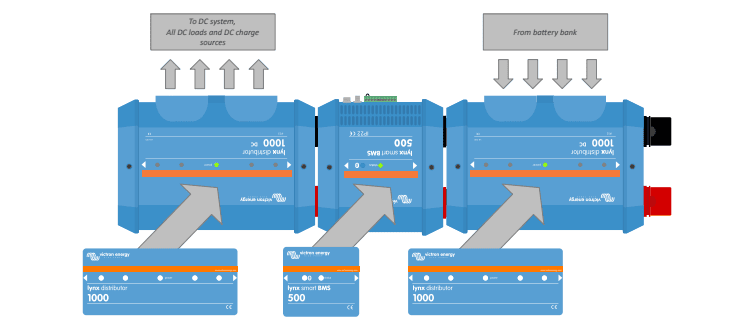

Lynx Victron Smart BMS 500 M10 installation examples

The following picture shows a system consisting of a Lynx Victron Smart BMS, two Lynx distributors and lithium batteries:

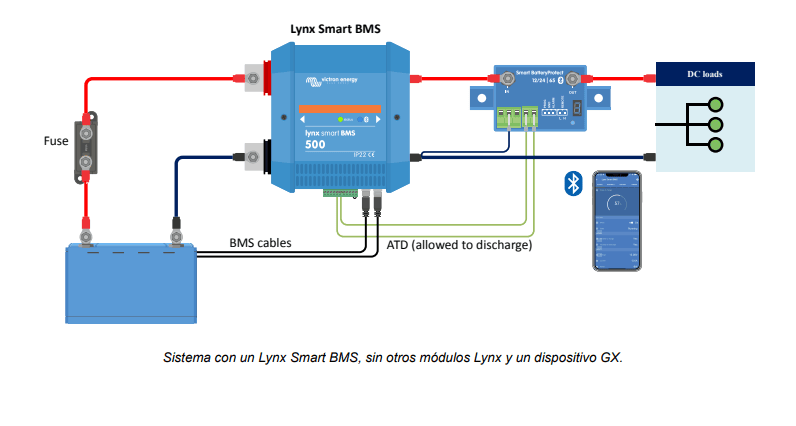

The following image is of a system consisting of a Lynx Smart BMS, no GX device and no Lynx distributors:

Lynx Victron Smart BMS 500 M10 Manual and datasheet - LYN034160210

Weight and dimensions

| Weight | 2,2 kg |

|---|---|

| Dimensions | 17 × 18,6 × 8 cm |

User feedback

Be the first to review "Lynx Victron Victron Smart BMS 500 M10 - LYN034160210" Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.